Tips to Know Before You Build a Chevy Stroker Engine

Planning a stroker build? Here are a few things you should know before you get started.

It wasn’t all that long ago (okay, LBJ was president and Bonanza was a hit TV show so maybe it was a long time ago) that a factory 327 / 350 hp small-block has serious street cred’ and Chevy’s 427 making 435 horsepower was boulevard king. Today, it’s a walk in the park to build a 500 hp small-block and a 650 hp big-block Chevy with purely aftermarket parts–but these engines enjoy lots of cubic inches.

The easiest way to get to those monster horsepower and torque numbers is to bump the cubes. The classic line that there’s no replacement for displacement has fed an entire culture of engine builders whose only goal in life is pushing the limits of displacement. We’re going to fan those flames by running through the popular small- and big-block Chevy stroker combinations to give you an idea of what’s possible.

There are dozens more bore and stroke options than are illustrated in these three family tree tables. Experimenting with your own custom bore and stroke combination can be fun and the math for computing these is very simple. The shortcut equation looks like this:

Bore x Bore x Stroke x 0.7854 x Number of Cylinders

As an example:

4.31 x 4.31 x 4.5 x 0.7854 x 8 = 525.2 cubic inches

To begin with the traditional small-block, the given standard is the ubiquitous 350. With its 4.00-inch bore and 3.48-inch stroke, at one time it was the largest production small-block Chevy. That was quickly followed by the 4.125-inch bore and 3.75-inch stroke 400 cousin and it didn’t take long for builders to grind the main journals on a 400 crank down to the 350’s smaller journal size, stuff it in a 0.030-over 350 block and create what became the omnipresent 383. For Chevy street enthusiasts, this is where the stroker world begins.

A quick deck clearance calculation for any piston and rod combo is block deck height – ½ stroke – piston compression height – rod length. So with a small-block deck height of 9.025, if we have a stroke of 4.00 inches, a compression height of 1.150 inches, and a rod length of 5.850 inches then: (4.00 /2) + 1.150 + 5.850 = 9.00 inches. Assuming that perhaps the deck has been shaved 0.010-inch, we would have a theoretical piston-to-deck clearance of -0.015-inch.

Adding a longer arm has become such a common practice that many overlook the details that make these packages successful. Adding a stroker crank is often not a bolt-in affair and can require some meticulous block massaging for. At the minimum, clearance needs to be checked everywhere! However, based on the learning curves of a generation of small-block engine builders, there are plenty of engine kits and packages out there that offer the exact parts you need.

Another area to consider is external versus internal balancing. The original 400 small-block and 454 big-block Chevys were both displacement escalations of earlier engines and their longer strokes required the expedient move to external offset balance weight. These are identified by the additional weights added to the harmonic balancer and flywheel/flexplate. Certain budget-based stroker crank packages reduce cost by retaining this external balance configuration but the proper approach is to make these stroker packages neutral balance.

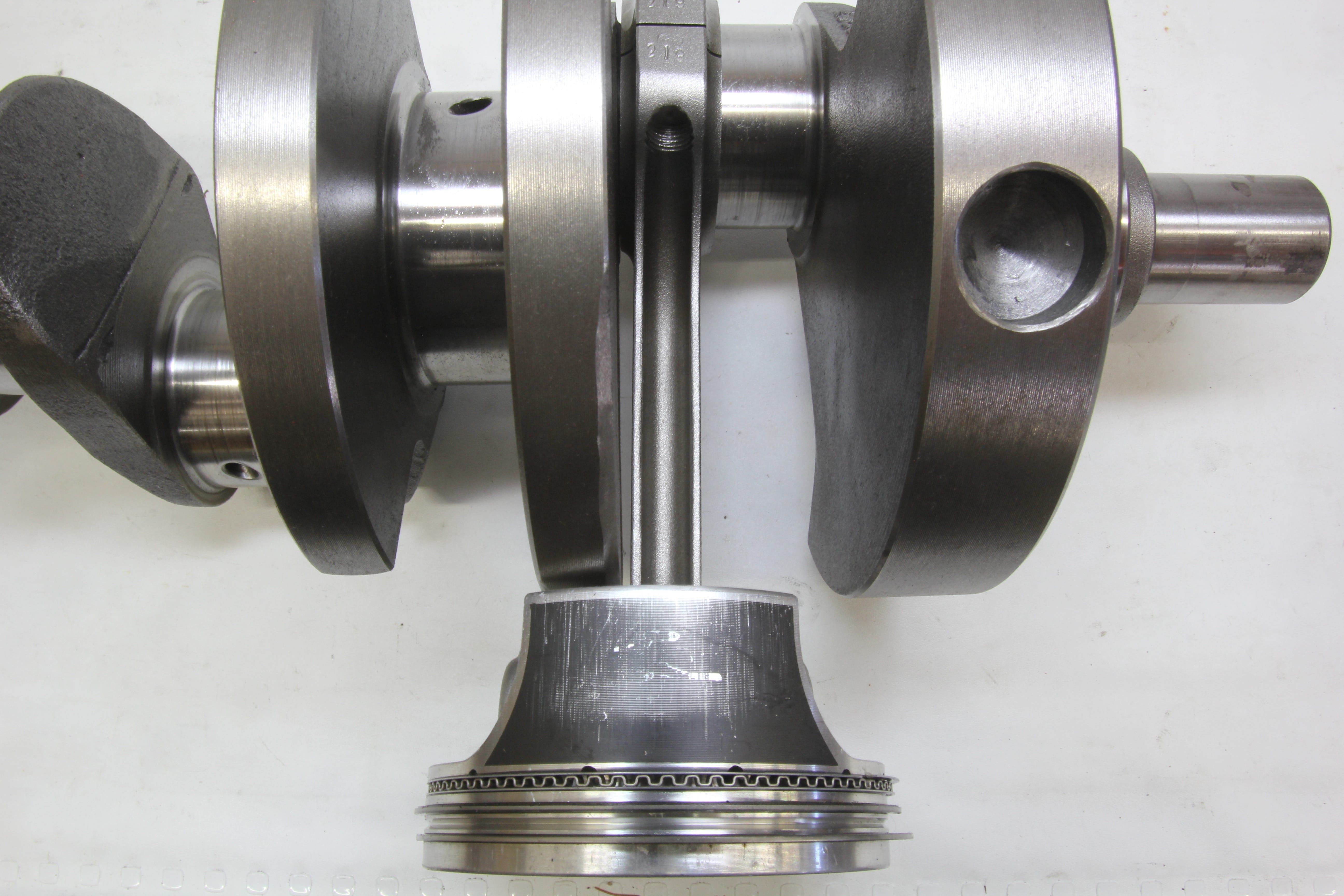

Adding stroke also closes the distance between the bottom of the piston skirt and the crankshaft counterweight. This is usually not a consideration unless you are mixing and matching parts, but it’s still a consideration. Shown is a used piston for mock-up purposes.

The reason this is important directly relates to higher engine speeds. Using a balancer or flywheel with what essentially becomes an eccentric weight hanging off both ends of the crankshaft is not conducive to longterm crankshaft or bearing life at high rpm. External balancing is acceptable for low rpm street engines because counterweight placed closer to the crankshaft’s fore-aft midpoint has less effect than weight placed at the extreme ends of the crank.

Another good reason for opting for a complete rotating assembly or at least purchasing the package from a professional engine builder is the concept of choosing a set of rods that are designed to work with the engine’s deck height and piston compression height. For example, pistons for a longer stroke can require a longer rod just to allow the piston to clear the counterweights when the piston moves to bottom dead center.

Stroking an LS engine is even more critical. GM shortened the length of the barrel or cylinder sleeves on all the Gen III and IV engines. Adding a longer stroke moves the piston over a greater distance, which also pulls the piston farther out of the bottom of the cylinder. With aluminum blocks limited to a minor overbore (unless you’re willing to step up to larger diameter sleeves like from Darton), adding stroke is limited to a maximum of 4.125 inches. Many conservative engine builders won’t go beyond 4.000-inches because even then the piston skirt begins to pull out of the sleeve slightly at bottom dead center (BDC).

When this longer stroke pulls the piston’s skirt out the bottom of the bore, this demands that the piston be designed to prevent the widest part of the piston (often called the gauge point) not extend past the bottom of the cylinder at BDC.

Building any engine means checking everything – including the deck height clearance between the piston at TDC and the block deck. For engines with steel rods, the minimum piston-to-head clearance is 0.040-inch but lots of builders push this to 0.035 or less – but that only works with minimal piston rock. Too little clearance and the piston will smack the cylinder head.

If the piston guide point extends past BDC, the piston will rock, and the end of the cylinder sleeve becomes a very efficient lathe that will peel aluminum right off the piston skirt– destroying the pistons. You don’t want that.

These are just some of the considerations that go into choosing a stroker engine package and why professional guidance is a great way to prevent small problems from becoming very expensive, bigger issues. After all, the whole idea here is to build a thumpin’ engine that will pin you to the seat back when you plant the throttle pedal.

Nearly all quality stroker cranks are offered in neutral or internal balance. If you have a choice between internal and external balance – always choose an internal balance. This eliminates the offset weights on the balancer (shown on this big-block) and flexplate/flywheel.

Below are some of the most popular Chevy stroker combos and their subsequent bores and strokes.

SBC

**Note: these combinations all assume a standard small-block deck height.

| Displacement (ci) | Bore | Stroke |

| 379 | 4.155 | 3.50 |

| 383 | 4.030 | 3.75 |

| 420 | 4.155 | 3.875 |

| 427 | 4.125 | 4.00 |

| 434 | 4.155 | 4.00 |

| 454 | 4.250 | 4.00 |

LS

| Displacement (ci) | Bore | Stroke |

| 358 | 3.90 | 3.75 |

| 404 | 4.01 | 4.00 |

| 418 | 4.03 | 4.10 |

| 426 | 4.065 | 4.10 |

| 429 | 4.08 | 4.10 |

| 427 | 4.125 | 4.00 |

| 441 | 4.125 | 4.125 |

| 454* | 4.185 | 4.125 |

| 502** | 4.165 | 4.60 |

* Using LSX block

** Tall deck block

BBC

| Displacement (ci) | Bore | Stroke |

| 496 | 4.310 | 4.250 |

| 510 | 4.310 | 4.375 |

| 540 | 4.500 | 4.250 |

| 557 | 4.500 | 4.250 |

| 565 | 4.600 | 4.250 |

| 572 | 4.560 | 4.375 |

| 588 | 4.560 | 4.500 |

| 598 | 4.600 | 4.500 |

| 632* | 4.600 | 4.750 |

| 665** | 4.600 | 5.000 |

| 780*** | 4.750 | 5.500 |

| 872**** | 5.000 | 5.550 |

*10.200 deck height (9.800 std)

**10.700 deck

***5.000-inch bore spacing block and 10.700 deck

****5.300-inch bore spacing and 10.700 deck