What is a Narrow Bearing?

Engine building is all about the details, and choosing the right set of engine bearings to match your crankshaft is an important one! Inside we investigate what a narrow bearing is and when you should use them.

It seems every day that there is a new post on social media about street engines making four-digit power. A killer late model Hemi with a blower easily pushes past 1,100 horsepower and Mike Moran has built an all-billet, twin-turbo engine that made 5,300 horsepower. The power numbers keep escalating and yet far less attention is paid to what it takes for crankshafts, pistons, and connecting rods to survive these ever-escalating, and easier-than-ever-to-achieve power levels.

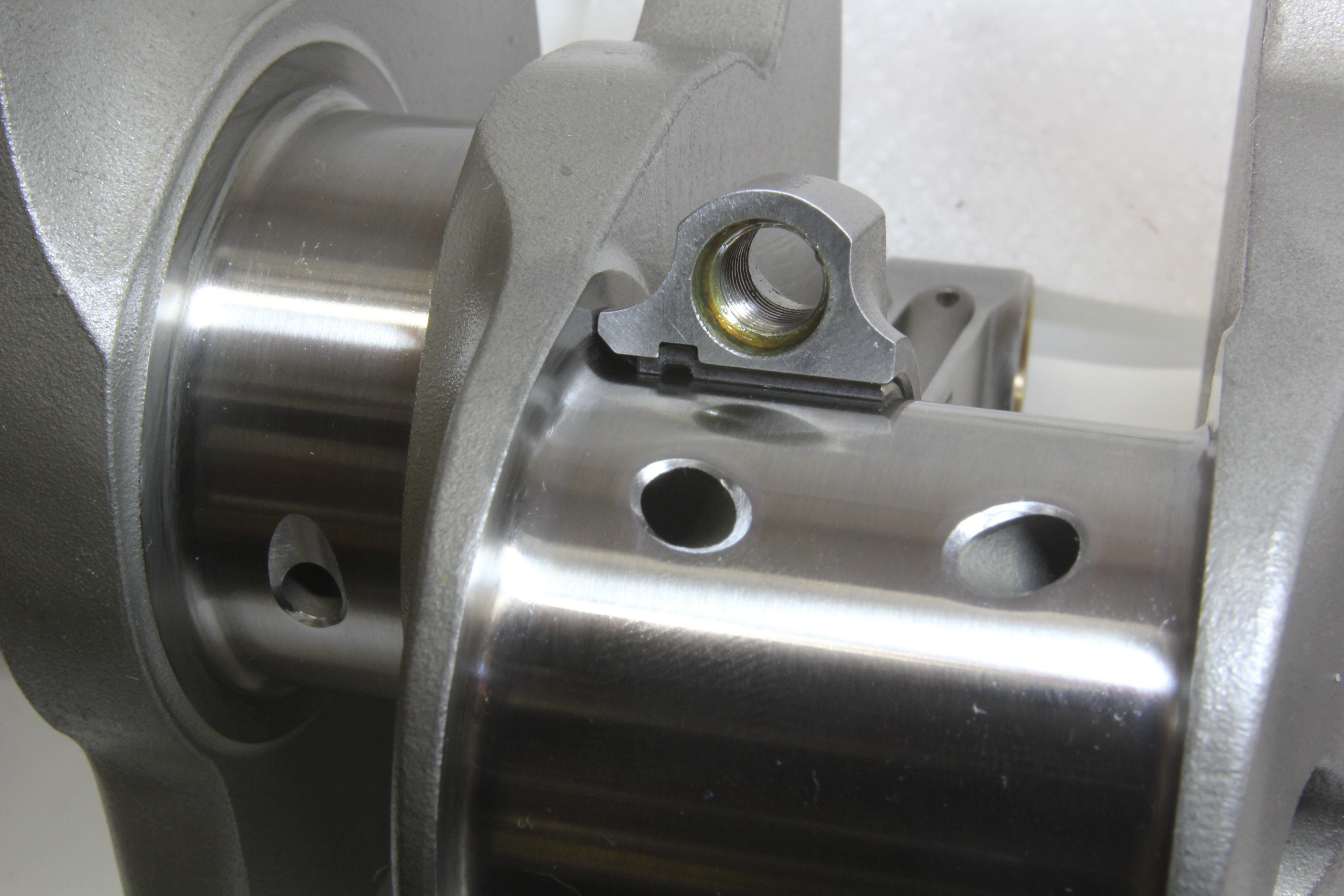

A fillet is a radius created in the transition from the rod or main journal to the vertical portion of the crankshaft. The radius improves crankshaft strength but requires a slightly narrower bearing compared to stock production bearings.

One small point that is often overlooked is connecting rod bearing width. That’s what this piece will focus on. But first let’s take a look at crankshaft design.

Everybody is aware that a 4340 alloy steel crankshaft is significantly stronger than the typical cast iron version. This alloy steel offers a higher tensile strength and is also more malleable – meaning forged steel is able to bend slightly under high loads. Cast cranks tend to be brittle and crack under high stress.

A further trick to improve durability is a simple technique known as a fillet radius. In a typical V8 crankshaft, stress occurs in several locations but concentrates in the corners created both at where the rod journal meets the cheek of the crank and also at that same position on the main journals. One way to minimize stress in sharp corners is to create a gentle radius. OE cast crankshafts sometimes undercut this corner to create the radius.

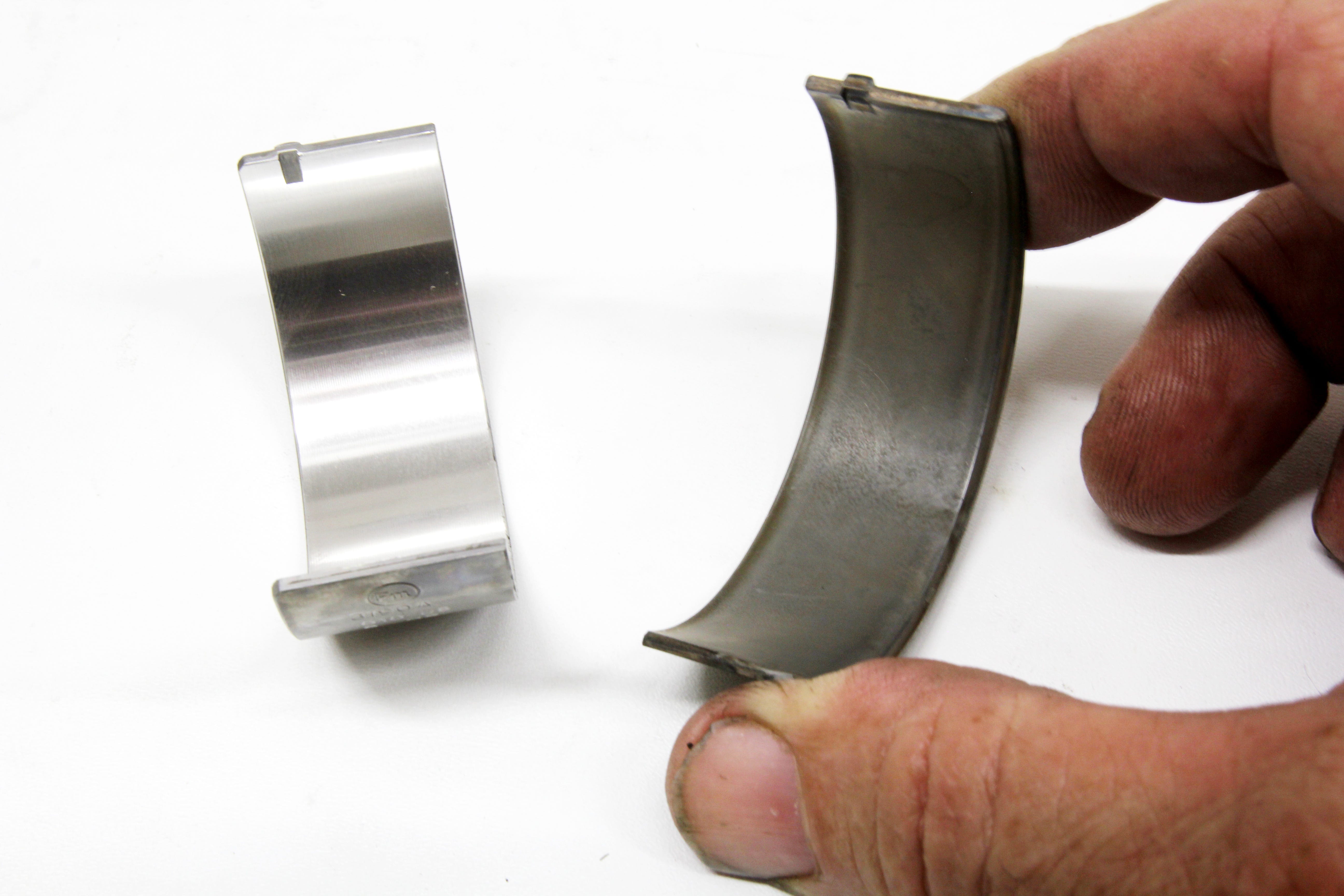

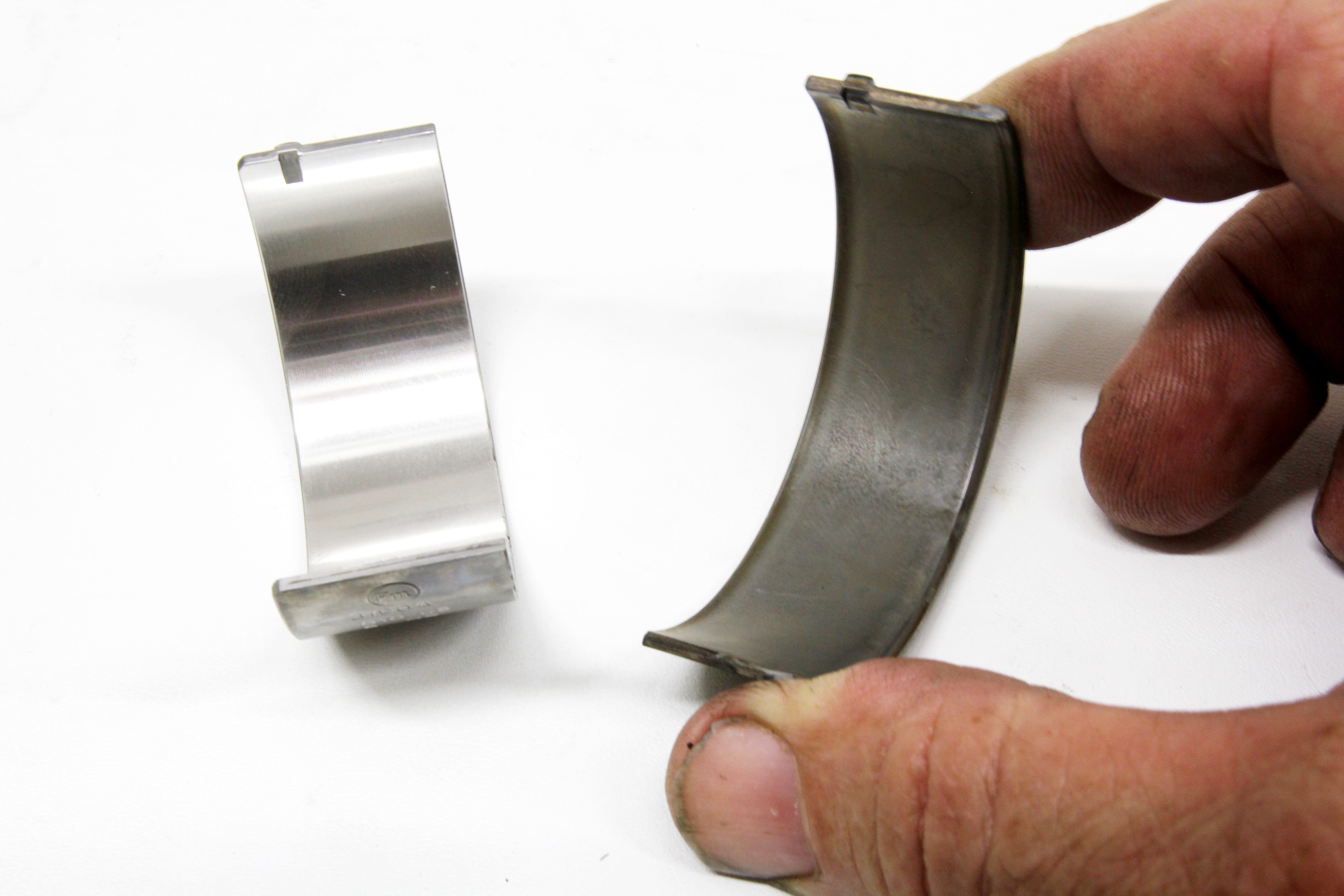

To illustrate the difference between a production bearing and a narrower performance rod bearing, we measured these two big-block Chevy Federal-Mogul bearings. The tri-metal high performance bearing measured 0.020-inch narrower than its OE aluminum cousin.

Forged crankshafts add material at this position. Then after the journal is machined, a very gentle radius is created that improves strength. However, this process also reduces the overall journal width. With a performance crankshaft, this reduced width demands a narrower bearing compared to a stock replacement version.

Taken as a generalized statement, stock replacement rod bearings are often slightly wider than their high performance bearing cousins. It’s beyond the scope of this story to get into bearing materials – but most stock replacement bearings employ an aluminum alloy while the majority of high-performance rod and main bearings use a much softer and more compliant tri-metal material that wears more quickly but will not peel or scrape like stock aluminum bearings.

In addition to narrowed bearings, performance bearings also employ a chamfer that is placed to match the chamfer on the rods where the rod meets the sides of the crank. This chamfer creates additional clearance. These chamfers must match the connecting rods so rod bearings are stamped upper and lower to ensure their proper placement. Be careful when selecting bearings since not all are chamfered.

To illustrate this point, we measured the width of a set of stock replacement aluminum Federal-Mogul connecting rod bearings for a big-block Chevy compared to a set of Federal-Mogul (Speed-Pro) performance tri-metal bearings. The stock aluminum versions measured 0.885-inch while the performance bearings were 0.020-inch narrower at 0.865-inch. Using the wider bearings on a performance forged steel crankshaft could cause the outer edges of the bearing to bind on the larger fillet radius of the crankshaft. This could cause immediate bearing failure, and at the minimum will cause bearing debris to be released into the oil.

There may be concerns about running a now 0.020-inch narrower bearing in terms of bearing loading but the small difference in width is really inconsequential since the width difference represents only a two (2) percent decrease in width in this big-block application.

This photo illustrates the clearance created between the edge of a narrowed rod bearing and the fillet radius. This prevents edge contact with the radius on the crankshaft.

Narrowed bearings also brings up the issue of rod bearing chamfers. Most performance rod bearings are designed with a chamfer on one side of the bearing to accommodate the large radius on the edge of the journal. Since the inboard side of the bearing avoids this fillet radius, there is no need for a chamfer on both side of the bearing. But with both upper and lower bearings, this demands that the bearing be placed in their proper orientation. Because the bearing is located by its tang, a chamfered bearing must be installed either as an upper or lower bearings since the chamfer will be on the opposite side for a lower compared to an upper bearing half.

It is important to note that there are basically two different rod and main bearing materials. OEM and some mild street engines can use aluminum alloy bearings (left), but the best plan for any performance engine is a tri-metal bearing using a very soft alloy of tin, copper, and lead.

This requires performance rod bearings with these chamfers to be marked “upper” and “lower”. Some bearing companies abbreviate this by using “U” and “L” as stamped on the back side of the rod. If these bearing halves are incorrectly installed, the bearing’s flat edge will face the fillet radius and create immediate bearing wear in this location–often the rod will even bind once the cap is torqued. Even without looking at the stamping on the bearing, an attentive engine builder knows the correct way the bearing should be installed by merely matching the bearing chamfer to the chamfered side of the connecting rod.

All of this falls under the category of important details that are required in the process of building a performance engine. Build it correctly and the engine will reward the builder with solid, reliable performance. Miss one or two of these details and reliability immediately becomes suspect.