High-Quality Connecting Rods and Crankshafts at Affordable Prices

At K1 Technologies, we strive to bring our customers high-quality, performance focused connecting rods and crankshafts at an affordable price, all backed by dedicated and knowledgeable customer service. As racers, builders, and enthusiasts ourselves, we understand our customers’ needs and are honored to have the opportunity to be your source for connecting rods and crankshafts.

What Sets Us Apart

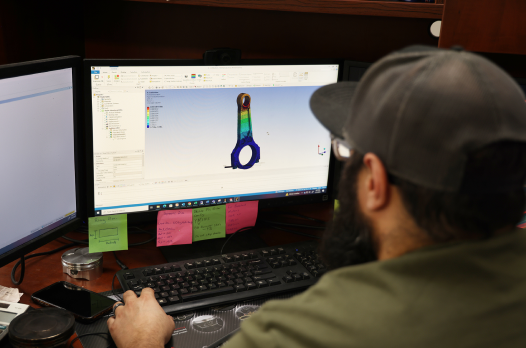

The K1 Technologies team focuses on bridging the gap between performance, reliability, and affordability. K1 connecting rods and crankshafts are engineered in-house at our Mentor, OH headquarters, applying years of combined racing and engine building experience along with feedback from real, track-tested situations. K1 Technologies components are manufactured to our exact specifications and are held to some of the tightest tolerances in the racing and performance industry. No steps or details are overlooked, with great attention to finish work and quality inspection playing key roles in setting K1 product apart from its competitors. A wide variety of sizes and applications are available, including everything from Sport Compact and European platforms to the ever-popular Small Block and Big Block Chevy and LS applications, as well as many more from Ford and Mopar. K1 even covers some custom and specialty sizes, providing a convenient solution for unique builds.

Materials and Components

All K1 Technologies connecting rods and crankshafts are manufactured using premium, 4340 steel. In addition to the strength-to-weight optimized design of K1 connecting rods, they also utilize industry-leading ARP fasteners, with ARP 2000 equipped standard and 625+ Custom Age bolts available as an upgrade for certain applications. Additionally, K1 rod bearing bore tolerances are held to +/- .0001″ in the big end, and bronze bushings are rolled into the small end, allowing for durable operation with full floating pins. Press-fit pins are also available on some rod sizes.

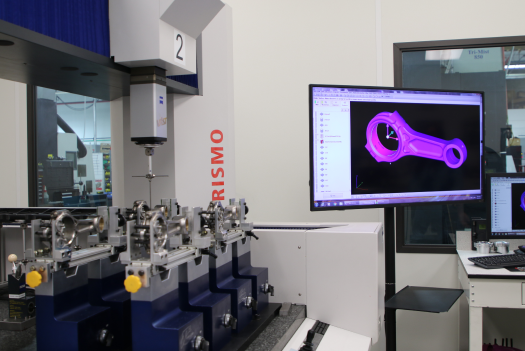

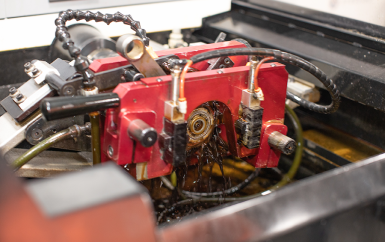

Processes

Benefits of quality material are only earned through quality processing, which is why K1 crankshafts are core-hardened to achieve increased tensile strength and fatigue life of the material and are 100% magnetic particle inspected to ensure material consistency to avoid potential failure points. Surfaces of rod bearing journals are carefully polished and nitrided, providing a consistent, low-friction surface translating to longer bearing life. Moving over to connecting rods, ARP bolts are installed and tightened to precise specifications prior to honing for accurate and repeatable bearing bore geometry. All K1 Technologies connecting rods are honed and dimensionally inspected in-house, as well as weight-matched into sets before packaging. All rotating, reciprocating, and total weight figures are noted with each set for convenient reference in the balancing process.